The Earth’s constant movement is an essential consideration in the building industry, as it directly affects the stability, safety, and longevity of structures. The Earth is constantly in motion due to several factors, and understanding these movements is crucial for architects, engineers, and construction professionals. Some of the key aspects related to the Earth’s movement and its impact on the building industry include rotation of the Earth, tectonic plate movement, earthquakes, subsidence, uplift climate-related movements, and sea level rise.

Factors such as site selection, structural design, and building materials are all considered during the commercial construction process. To prevent materials from destructive failures, we must accommodate for movement. Take tile, for example. Ceramic and porcelain tile, by its very nature, is extremely dense and strong, making it an excellent choice for finished floor and wall coverings. However, by the same token, it is not very flexible. For this reason, movement joints are critical to the success and longevity of the tile assembly. Whether it’s thermal, shrinkage, freeze/thaw, or structural movement, tile and stone installations are constantly subjected to various types of conditions. Failing to incorporate movement joints into the installation will almost certainly guarantee cracks and tenting in the long run, leading to costly repairs or replacement.

A movement joint, or expansion joint, is a deliberate separation or gap provided in a building or structure to accommodate the natural movement and deformation caused by various factors, such as temperature changes, settlement, seismic activity, or moisture variations. These joints allow different parts of the structure to move independently without causing damage or undue stress to the overall building.

The primary purpose of movement joints is to prevent the formation of cracks, fractures, or distortion in the building components that can occur when materials expand or contract due to changes in environmental conditions or external forces.

Whether residential or commercial, movements joints are mandatory; not voluntary.

In tile installation, movement joints are essential to accommodate the natural expansion, contraction, and shifting of materials due to temperature, moisture, and structural settling changes. Movement joints prevent the tiles from cracking or popping out of place. There are several types of movement joints used in tile installations:

The exact type and placement of movement joints can vary depending on factors like tile size, material, substrate, environmental conditions, and project specifications. Following the industry standards and manufacturer’s recommendations is crucial to ensure a durable and long-lasting tile installation. A qualified tile installer or professional in the field can help determine the appropriate type of spacing of movement joints for a specific project.

The importance of an expansion joint in tile installation cannot be overstated. By incorporating expansion joints, tile installers can ensure a stable, durable, and aesthetically pleasing surface that stands the test of time. The diagram below considers this an expansion joint due to the full-depth assembly.

The Tile Council of North America (TCNA) provides general movement joint guidelines for tile and stone applications. This section is called EJ171 Movement Joint Guidelines for Ceramic, Glass, and Stone.

The general rule for placing movement joints in ceramic tile and stone installations is to have an expansion joint every 8 to 12 feet in each direction, with additional joints at all perimeters, changes in plane, and transitions to other surfaces.

This general rule accommodates the natural expansion and contraction of ceramic tile and stone materials due to temperature changes and other external forces. Properly placed movement joints help prevent the occurrence of cracks and other issues that may arise from the differential movement of the materials.

It‘s important to note that specific installation requirements and guidelines may be subject to updates and revisions over time. For the most current and accurate information regarding movement joint requirements for ceramic tile and stone installations, it is recommended to refer directly to the latest version of TCNA’s EJ171 publication or consult with a qualified tile installation professional.

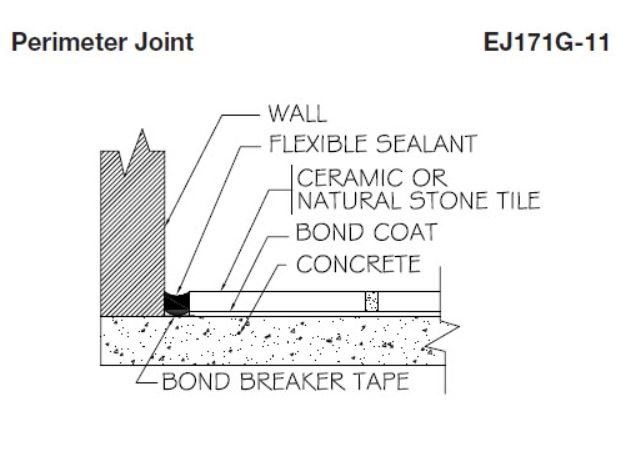

The perimeter joint, also known as the perimeter gap or edge joint, plays a significant role in tile installation. It refers to the space left between the tiles and surrounding elements where the tile is installed. The diagram below represents the view of a perimeter joint.

TCNA EJ171G-11 states that perimeter joints are essential to accommodate building movements and prohibit cracks in the substrate from telegraphing to the tile finish. This detail illustrates a perimeter expansion joint where the tile floor terminates into an inside corner of the tile walls.

Section EJ171G-11 also states that all underlying movement joints in the substrate must continue through the tile assembly. This means that tile installation requires additional movement joints in conjunction with honoring the substrate movement joints. If there is a mortar bed over the substrate, then the movement joint must be continuous through it to the tile surface, which is considered an expansion joint. If the tile is being bonded directly to the substrate, and there is no substrate movement joint continuing up from beneath, it is called a generic movement joint.

Movement joint recommendations for food service, corporate workplace, hospitality, and multi-family projects are crucial to ensure the integrity and longevity of these installations. Here are some key considerations and recommendations for incorporating movement joints in commercial installations:

By following these movement joint recommendations, commercial buildings can maintain durability, enhancing the overall safety and aesthetics of the facility.

To ensure a long and successful installation, strategically incorporating movement joints and using the proper types of sealants are a must – not an afterthought. (If you’re familiar with past Tile Talk Blogs, you’re likely familiar with Mapei.)

As always, for tile technical assistance. contact any member of the QA&T Team. Your success equals our success.